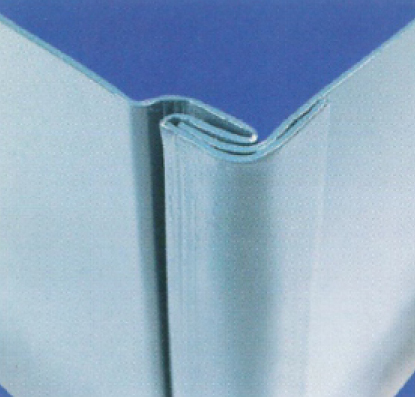

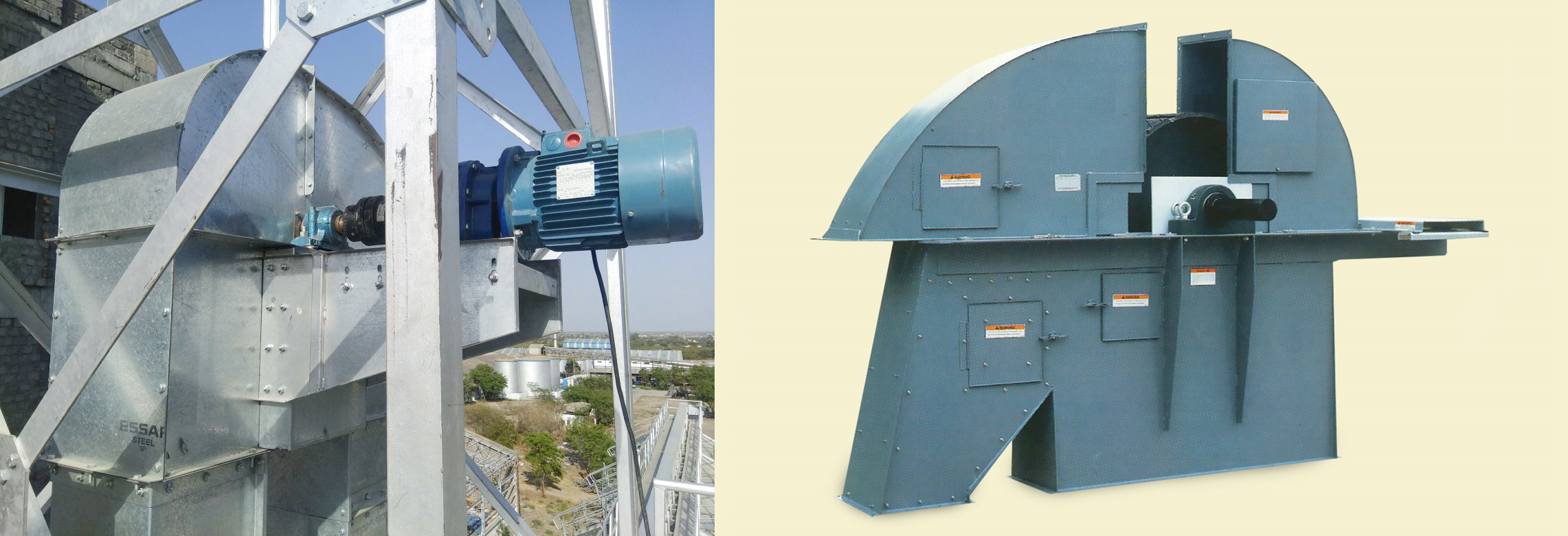

Legs: All Bali Group elevators leg sections feature Pittsburgh-type lock- formed construction. This dramatically increases leg strength, and also provides a moisture and dust-tight seal-from top to bottom. This means Bali Group elevators already comply with future air-quality regulations. Legs are constructed using heavy duty production jigs and dies. This means a snug fit, and no unnecessary assembly time or modifications. Bali Group elevators models 16 and 24 also feature a channel frame inspection section. A large front viewing door and removable panels on each side make belt and cup maintenance easy.

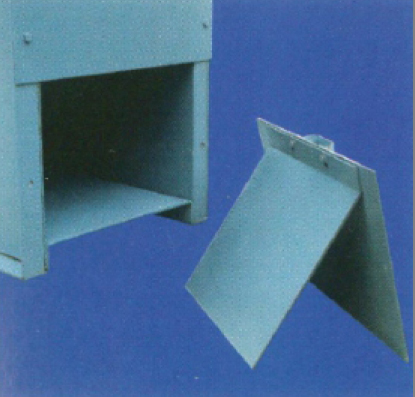

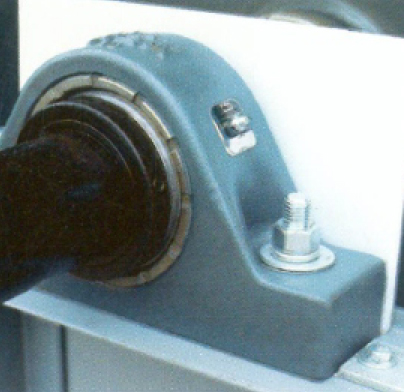

Boot: The foundation of Bali Group elevator performance is the boot section. We start with heavy gauge steel and jig-weld the sides and bolt the end panels. Structural strength is enhanced using vertical steel gussets. Easy access clean-out doors provide a weather proof seal, but remove in a snap. Like the head, Bali Group elevators boots feature heavy-duty pillow block bearings with ACME screw take-ups.

Belt: Long belt life is assured from the PVC synthetic fabric belt or super oil resistant belt depending on application. This design provides protection against oils, moisture and fire. It even resists the effects of fertilizer acids. Each belt is also engineered to reduce stretch. Belt wear is reduced through our use of larger than normal pulleys.