Conveyors

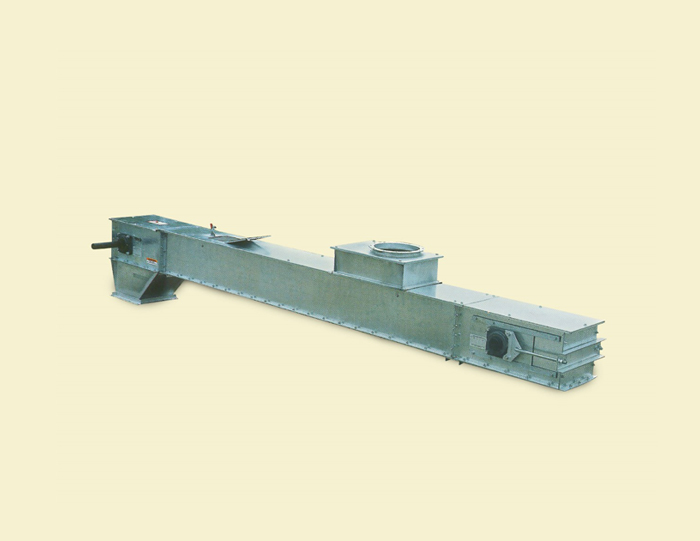

Home » ConveyorsIntermediate Section: Rigid steel troughs make the Bali Group Conveyor a better choice. Rugged 8 gauge (4 mm) steel lines the bottom, and 11 gauge (3 mm) steel sides round out the conveyor trough. The bolt-together construction is ideal for overseas shipment because of reduced cubic footage. Bottom sections are staggered to assure a smooth connection- eliminating misalignment.

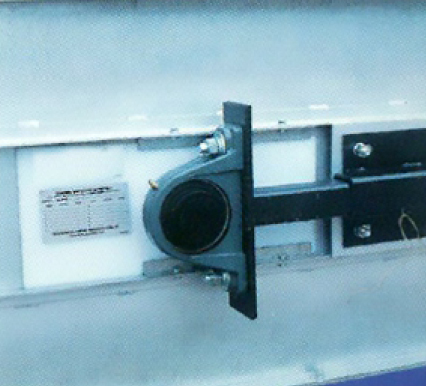

Tail Section: A heavy-duty shaft together with high-capacity bearings make this tail tough as nails. The heavy 8 gauge (4 mm) steel bottom can take a pounding. All tail sections include sprocket, take-ups and cover. Your Bali Group Conveyor tail can be easily modified depending on your application and capacity requirements.

Chain: The heart and soul of the Bali Group Conveyor system is the use of steel pintle chain and UHMN paddles. There's no steel-to-steel interaction to cause wear, so you'll get smooth operation year after year. The smaller pitch chain has larger cast sprockets which provides more tooth to barrel contact and eliminates chain jump. Bali Group Conveyor's unique annular ring design on the teeth of the sprockets evens out torque from the barrel to the sidebar of each link. This provides even wear and assures longer chain life. The open barrel design also eliminates material buildup.

Inspection: Bali Group Conveyor hinged inspection door provides quick access for observing operation. This access is screened for safety, and when closed is dust and weather tight.

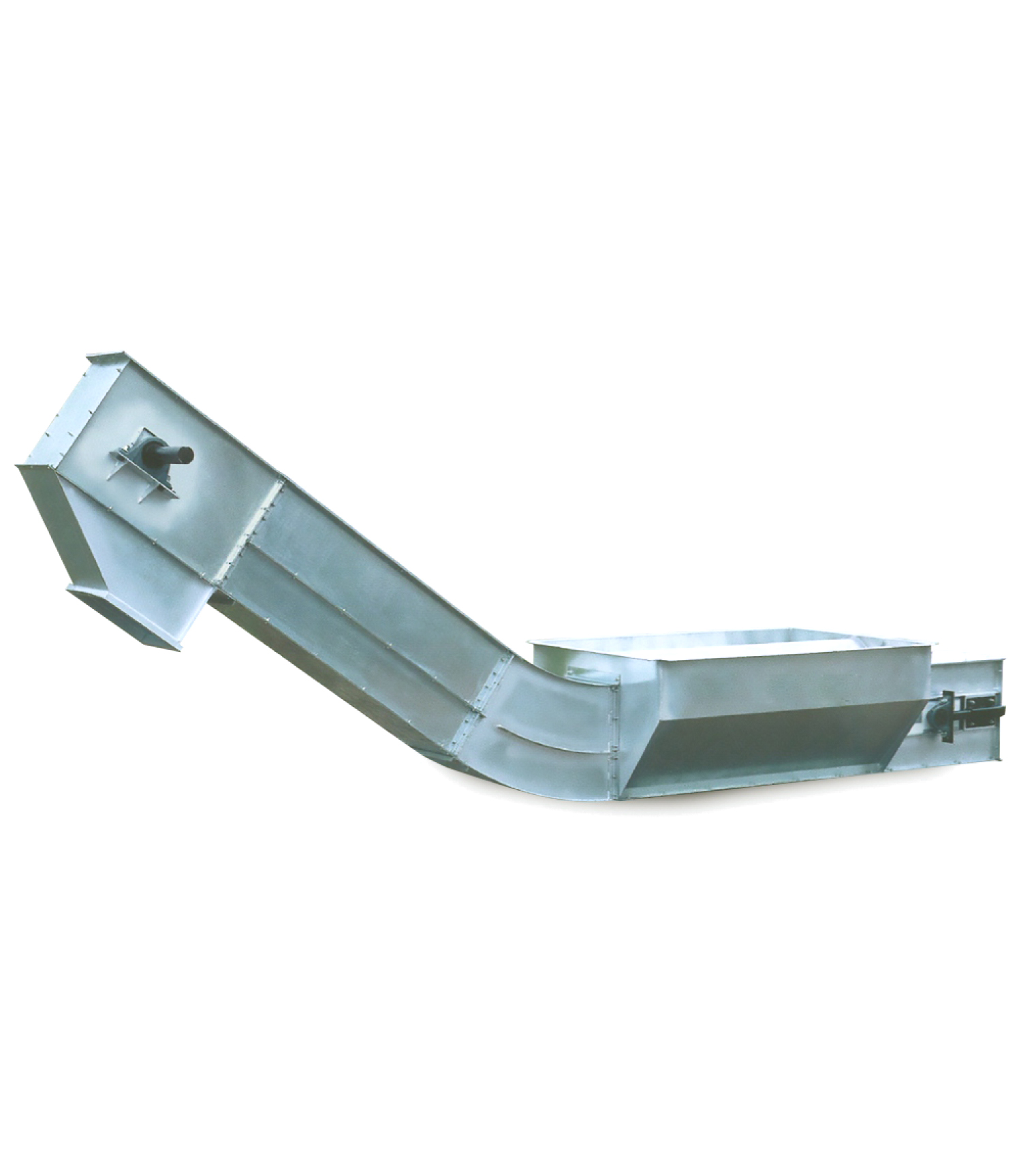

When you need to move material horizontally or on an incline.

Bali Group offers a number of hard-working, long-life conveyors including belt and screw models -as well as the Bali Group Conveyor, our unmatched chain-type en masse drag system.

- Available in a wide range of capacities and widths.

- Available in galvanized steel, painted steel or stainless steel construction.

- Distribution to overhead silos for loading or unloading.

- Conveying to bucket elevators for load-out or distribution.

- Transportation of grain from the dump pit.

- Special applications or designs up to 45-degree incline.

- Pit bypass conveyor hoppers for reducing grain damage - also available with a heavy-duty driveway grate that can handle the weight of multiple-axle hopper trucks.

Bali Group Conveyor are perfectly suited for:

Bali Group Conveyor are available with these options: > Models for use in limited space installations.