Flat Bottom Silos

Home » Flat Bottom Silos

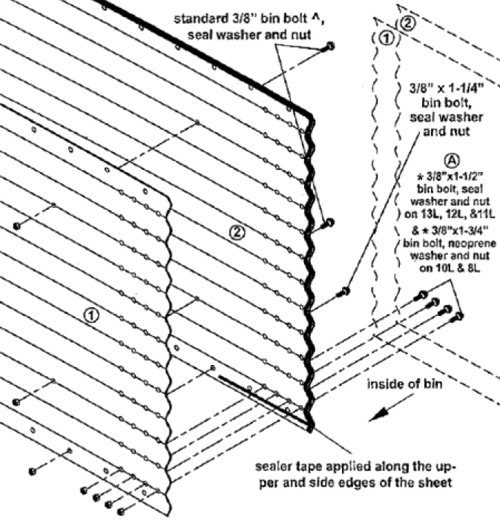

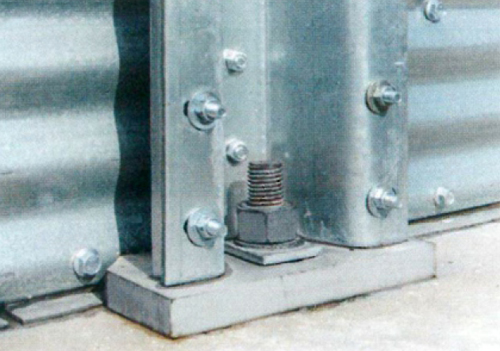

Bolt-on base angle provides a strong finished edge to bin bottom and secure seal of bin to foundation when a sealer is added-providing greater integrity over competitors' pre-formed angles that are simply rolled into the sheet.

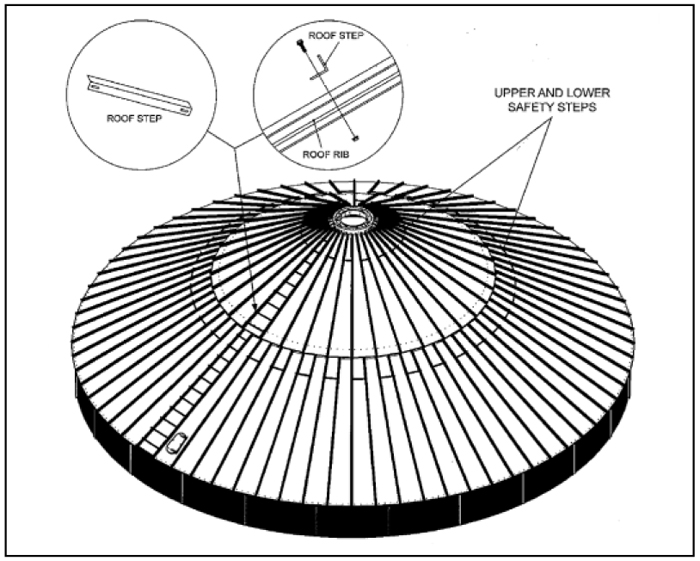

Proprietary state-of-the-art roll former controls the distance between holes from rib-to-rib, not from the edge of the coil like competitive products. The result: Higher quality roof sheets that fit better- with bolt holes that line up every time. Bolts drop right in place. That means trouble-free, labour-saving, frustration-free installation on site.

G115 galvanizing of stiffeners provides up to 27% longer life. Most stiffeners are ASTM A653 Grade 55 with 55K yield and 70K tensile strength.

12 gauge splice ensures that stiffeners are properly butted to effectively transfer vertical sidewall load to the foundation.

Heavy duty wind rings are easily attached to the stiffeners on bins requiring this extra measure. Pre-punched wind ring holes and special attachments simplify installation.

"Hat shaped" stiffener design is proven through engineering studies to be the preferred shape for commercial bin stiffeners. This design carries the full vertical load to the foundation.