Hopper Bottom Silos

Home » Hopper Bottom Silos

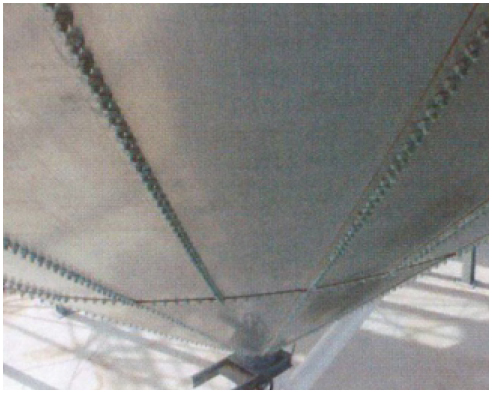

Galvanized panels ranging from 2.5mm to 4mm Grade 50 are designed to withstand hoop and top tension loads throughout the range of sizes available. Cross braces keep tank evenly braced during loading.

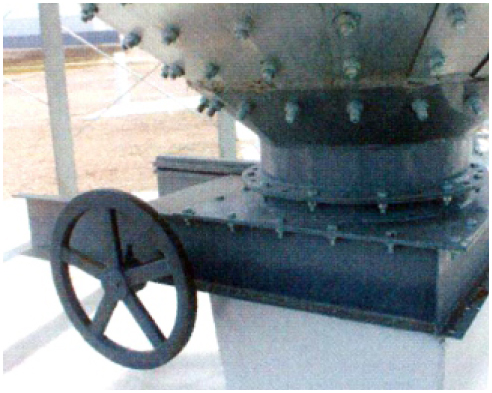

Manual rack and pinion gate controls flow from the tank and comes standard with all commercial hopper tanks.

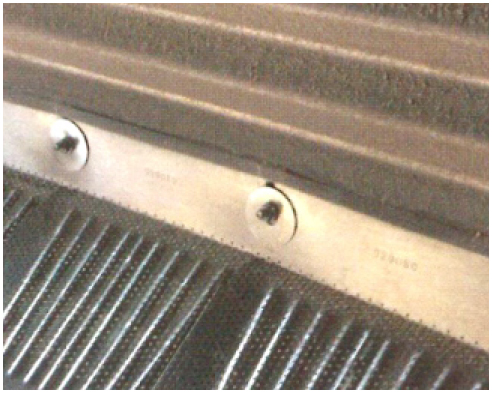

Shedder plate, supplied with all models, is a perforated component attached to the sidewall at an angle that matches the hopper cone angle. The shedder plate eliminates commodity hang-up were the sidewall connects to the cone.

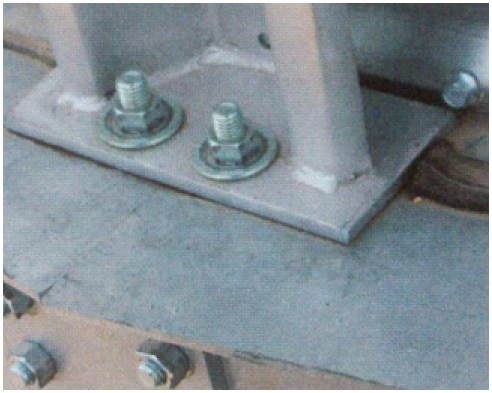

Heavy base plates welded to the bottom end of the support columns provide a positive attachment to the concrete foundation with proper anchoring.

Cone bottom is ideally designed for full clean-out and to ensure that majority of the product is emptied with minimal carryover.